Date

Client

OVAMLocation

BuggenhoutStatus

FinishedComplex demolition and cleanup of heavily contaminated industrial site

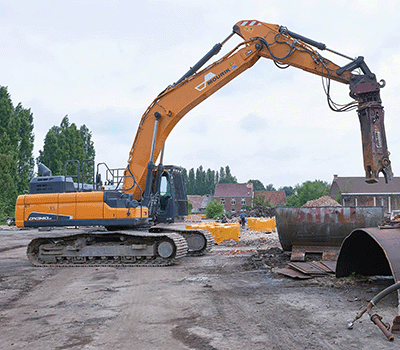

At the former Alvat site near the Schelde, metal drums were once cleaned for reuse, until the company went bankrupt in 1995. What was left behind was a heavily polluted industrial site, adjacent to a residential area, which no one was interested in. The buildings and installations, as well as the waste, remained unattended and neglected for years. Until OVAM decided to buy the site and clean it up completely. In Mourik, OVAM found a partner for the first phase of this complex remediation project, namely the above-ground demolition including waste management and asbestos removal.

Demolition and dismantling

The site contained 26 dilapidated buildings, workhouses and offices, collectively about 63,000 m³. We demolished these selectively, removing 200 support columns with asbestos cement formwork. To do this, we first had to clear about 12,000 m² of floor space from vegetation, asbestos-containing debris and other waste. There was also a 35-meter-high chimney between the buildings, which we took down. In addition, we dismantled the old water treatment plant, storage tanks and machinery. We crushed the uncontaminated debris on site and used it to level the site at the end of the project.

Asbestos and chemicals safely removed

The site contained a lot of asbestos. Before we could begin the demolition and dismantling, we removed and disposed of: asbestos cement roofing (approx. 9,000 sq. m.), possibly asbestos-contaminated roofing (approx. 1,300 sq. m.), asbestos-containing wall cladding (approx. 820 sq. m.), asbestos cement-containing ducts (approx. 70 m) and sewage (approx. 100 m). IN addition to asbestos, there was other contamination on the site. We emptied and cleaned 9 storage tanks for chemicals, ranging in volume from 3 to 60 m³. We transported the residues, along with all other hazardous waste, to approved treatment centers.

We always strive for the most sustainable execution possible. A good example here is the water treatment plant. The old water treatment plant still contained 600 m³ of water contaminated with oil and heavy metals. Based on our experience, we purified that water on site instead of transporting it to a treatment center. That saves a lot of transportation and emissions. We arranged the permits and then treated the water on site with our own mobile water treatment plant, consisting of an oil-water separator, a sand filtration unit and an activated carbon filter.

Contact

B-2030 Antwerpen